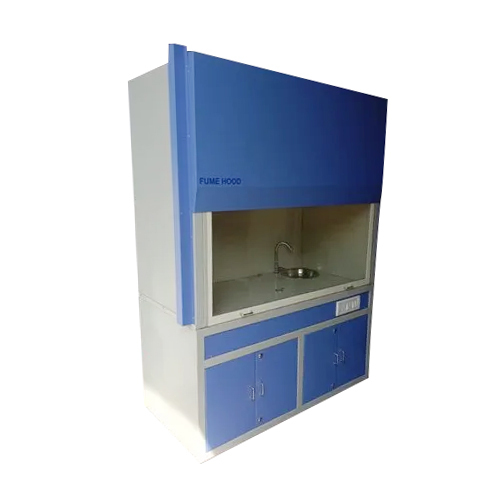

Laboratory Fume Hood Stations

50000 INR/Piece

Product Details:

- Lighting Yes

- Application Laboratories

- Material Stainless steel

- Voltage 230 Volt (v)

- Click to View more

X

Laboratory Fume Hood Stations Price And Quantity

- 50000 INR/Piece

- 1 Piece

Laboratory Fume Hood Stations Product Specifications

- Yes

- Laboratories

- Stainless steel

- 230 Volt (v)

Laboratory Fume Hood Stations Trade Information

- Cash in Advance (CID)

- 10 Piece Per Month

- 5-7 Days

- Asia Middle East Africa

- All India

Product Description

Laboratory Fume Hood Stations are designed to provide a safe and healthy working environment for laboratory personnel by removing hazardous fumes, particles, and vapors from the air.

Types of Laboratory Fume Hood Stations:

1. Conventional Fume Hoods: The most common type, using a combination of airflow and filtration to remove contaminants.

2. Ductless Fume Hoods: Using filters to remove contaminants, these hoods do not require ductwork.

3. Recirculating Fume Hoods: Using a combination of airflow and filtration, these hoods recirculate cleaned air back into the laboratory.

4. Walk-In Fume Hoods: Larger hoods that allow personnel to walk in and work inside.

5. Specialty Fume Hoods: Designed for specific applications, such as perchloric acid or radioisotope handling.

Key Features:

6. Airflow and Filtration: Provides a safe and healthy working environment by removing contaminants from the air.

7. Chemical Resistant Materials: Constructed from materials resistant to chemicals and corrosion.

8. Adjustable Airflow: Allows for adjustment of airflow to accommodate different laboratory procedures.

9. Safety Features: Includes features such as emergency stop buttons, alarm systems, and fire suppression systems.

10. Energy Efficiency: Designed to minimize energy consumption while maintaining a safe working environment.

Technical Specifications:

11. Airflow Rate: 50-1000 CFM (cubic feet per minute)

12. Filter Type: HEPA, activated carbon, or specialty filters

13. Noise Level: 50-70 dBA

14. Power Requirements: 115/230V, 1-3 phase

15. Dimensions: Variable, depending on the type and size of the fume hood

Applications:

16. Laboratories: Research, educational, and industrial laboratories.

17. Pharmaceutical and Biotechnology: Handling of hazardous chemicals and biological agents.

18. Chemical and Petrochemical: Handling of corrosive and flammable chemicals.

19. Environmental Monitoring: Analysis of air, water, and soil samples.

20. Academic and Research Institutions: Teaching and research laboratories.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free